Beer tanks

Beer tanks represent a groundbreaking solution for the distribution and sale of draft beer, enabling breweries to deliver their product to consumers while maintaining its original quality. These tanks significantly reduce quality losses resulting from transportation, storage, and connection to the beer line at the point of sale.

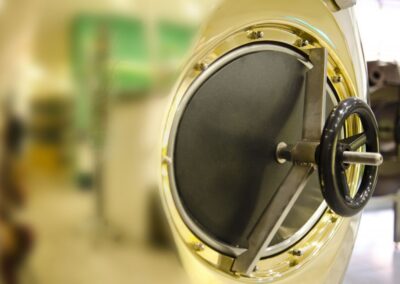

At the core of this system lies a welded pressure vessel, a tank equipped with fittings for filling and discharging pipes, air pipes, and a manhole with a cover.

Typically, the tank is installed at the customer’s facility, such as a restaurant or beer hall, often within a refrigerated cellar or container. In cases where a refrigerated room is unavailable, double-jacket cooled tanks can be utilized.

With this system in place, the beer follows a specific route from the producer to the consumer:

- The beer is filled into a tank truck at the brewery.

- The tank truck transports the beer to a restaurant where beer tanks are installed in a designated area and connected to the internal beverage distribution piping.

- The beer is pumped from the tank truck into a tank, usually equipped with the “bag-in-tank” system.

- Air is pumped between the tank wall and the bag, propelling the beer into the dispensing tower and ultimately into the serving glass via the tap.

The primary advantage of this solution is that the beer remains shielded from air or other gases, ensuring it does not become stale.

LUKR CZ provides a comprehensive service in the field of tank technologies. Our team of experienced specialists takes care of everything, ranging from manufacturing the product in our own facility to its installation and potential servicing.

Our tank offerings include:

Volumes:

- 250 liters

- 500 liters

- 1000 liters

Finishing options:

- Stainless steel

- Cooper

- Brass

- Wood

- Painted

- Foll with print

Jacket systems:

- Single-jacket (designed for installation in a refrigerated cabinet in the cellar or a glass box within the restaurant)

- Double-jacket – refrigerated (intended for installation within the restaurant itself)